|

Micro welding results in: Micro welding results in:

- Decreased downtime

- Increased tool life

-

Enormous time-savings

- Significant cost savings

With the combination of expertise and knowledge of a micro-dimensional welder, weld can be placed only where you want it, with its size and shape being maintained within specified tolerances. The result is less downtime and less re-machining, which frees up staff(e.g., mold makers) to concentrate on other functions.

Some micro-dimensional welders also have the ability to maintain and re-establish straightness and flatness of geometrically challenged components. Components can be returned straighter and flatter than when they were shipped.

For small cosmetic repairs, a true micro-dimensional welder can apply weld accurately and sparingly enough so that the piece can be fe-finished by hand. This can eliminate costly setup time. Techniques to minimize or eliminate sink also have been developed. A few elite welders are able to create "negative sink", or raised steel around the welded area, that is usually undetectable after refinishing.

Some manufacturers are taking advantage of these abilities in their design and manufacturing processes. Large, flat surfaces with protruding features do not always need to be inserted or machined around, which takes more time. Protruding features can be formed with weld on the finished surface afterward. This process can eliminate the EDMing or milling of insert pockets, while reducing programming time and a host of other processes.

Many organisations have streamlined their insert production by wire-EDMing insert profiles to finished dimensions and simply welding on the "heel" afterward. This saves milling and grinding time. Gate and high-wear areas can be added after heat treating for increased Rockwell and wear resitsance. Such practices have proven effective in rapid prototyping, where welding can eliminate weeks of unneeded work.

The Micro Arc welding team not only understands micro-dimensional welding, they also understand metallurgy, mold design, mold making and machining. Because of their experience they can provide a quick turn around at a reasonable price - and they can tell the customer whether micro-dimensional welding is the best repair solution.

Depending on the nature of the repair, the process at Micro Arc often begins with a team meeting. The combined expertise of the Micro Arc team ensures the best solution for every welding problem.

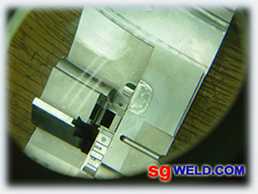

Once a solution is chosen, a trained professional micro-dimentional welder begins the task of welding to the most precise requirements. All welding stations at Micro Arc uses state-of-the-art Weldlogic equipment. Using low amperage welding under a microscope with wire that may be as fine as a human hair, the welder can:

- Achieve tight tolerances

- Manage distortion and sink

- Weld in hard-to-reach areas

A fully equipped machine shop is available on site for making special gauges, fixtures and heat sinks. To ensure the highest quality, two welders inspect every weld before the mold is shipped to the customer.

The company you choose can mean the difference between down time of five hours or five days. Micro Arc typically completes this entire process within 24 hours.

All repairs are 100% guaranteed. |